Industrial Cameras, Industrial Imaging and Machine Vision - Wholesale Distributor - Aegis Electronic Group

ROHS COMPLIANCE AND INDUSTRIAL IMAGING

ROHS COMPLIANCE AND INDUSTRIAL IMAGING

There is a cross roads of supply chain management, social responsibility and protecting the environment. ROHS compliance for industrial imaging and factory automation applications are in that crossroads. It assures manufacturers their vendors are meeting the highest standards for reducing harmful elements.

WHAT IS ROHS COMPLIANCE?

A supply chain vendor who is ROHS compliant has gone the extra mile to prove potentially harmful elements are minimized. Their components are lower in harmful elements like mercury, lead, cadmium, Cr VI, PBB, PBDE, DEHP, BBP, DBP, and DIBP (acronyms explained here.) While seven of those materials are abbreviated here, they are known to scientists as toxic to the environment when discarded in unprotected landfills. The dumping of consumer electronics into landfills years ago prompted the environmental concerns that led to ROHS.

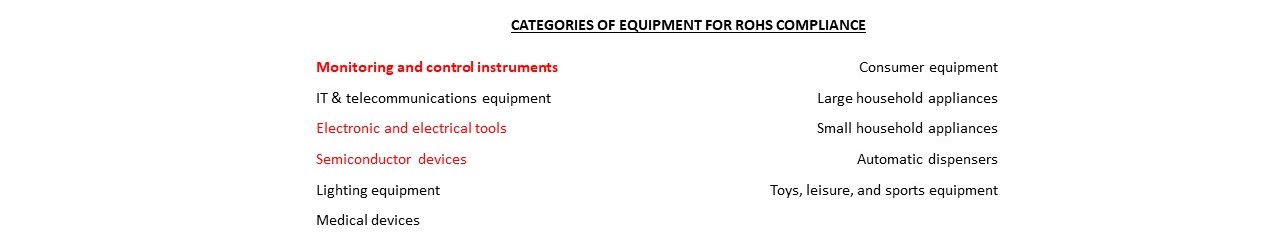

The European Union passed the Restriction of Hazardous Substances (ROHS) in 2003. Subsequent revisions have kept the focus on the central intent of addressing consumer electronics. The current categories addressed are listed below. In red are categories of equipment that are potentially in use for factory automation, industrial imaging, quality inspection and security camera applications:

HOW ROHS COMPLIANCE APPLIES TO INDUSTRIAL IMAGING

Industrial imaging systems use the global supply chain. Global supply chains have been of tremendous help to OEM’s (original equipment manufacturers). It has allowed Japanese machine vision lenses to be mated with Lithuanian lasers and Chinese circuit boards using Californian programmers to make automated measuring devices to speed up quality assurance checks. The brand putting all those components together is the OEM. Their ability to reduce toxins to the environment is enabled in part by choosing vendors that are ROHS compliant. The adoption of corporate social responsibility statements in manufacturing has been happening for over 14 years (link).

WHAT IT TAKES TO BE ROHS COMPLIANT

Obtaining certification is a three step process. First is testing, followed by a process audit, then concluded with a documentation review. This is critical for any products sold into the European Union. One statement clarifies it as: “Manufacturers of hazardous material must become RoHS compliant in order to sell and distribute the product inside of the European Union, which is exactly why it is so vital for a company to obtain these credentials." (source link)

CHOOSING VENDORS WITH ROHS COMPLIANCE

Choosing vendors that are ROHS compliant may be easier then you think. Look for a link on their website to their certificate. Or open a conversation with their sales team on the topic. Anyone sourcing components for an quality inspection, industrial imaging, CCTV or factory automation application has a chance to participate in the earth-friendly crossroads that ROHS compliance provides.